by Metal Mechanical Finishing | Aug 11, 2022 | Metal Finishing

Looking into the benefits of metal finishing? There are a ton of perks that come along with pursuing this craft. However, without expert knowledge, they only create minimal change. Here are the traits that separate your surfaces quickly with expert metal finishing....

by Metal Mechanical Finishing | Apr 14, 2022 | Deburring, Metal Finishing

Product lines need to run effectively for a business’s output to be maximized. Here are a few tips on identifying issues and points of improvement, as well as what deburring can do to give the line an efficiency edge as well. How are you operating the...

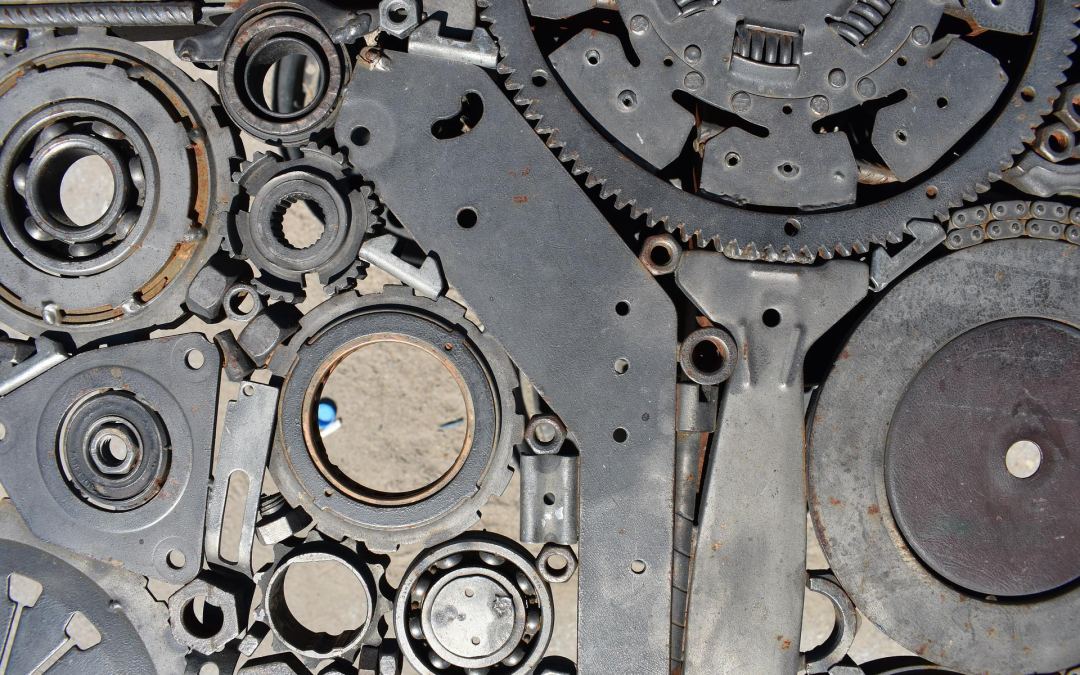

by Metal Mechanical Finishing | Nov 14, 2021 | Deburring, Metal Finishing

Metal finishing aids in the reduction of wear and tear on metallic products. Aside from aesthetics, it has a wide range of industrial applications. It helps to improve electrical conductivity, torque resistance, and metal solderability, among other things. Why...

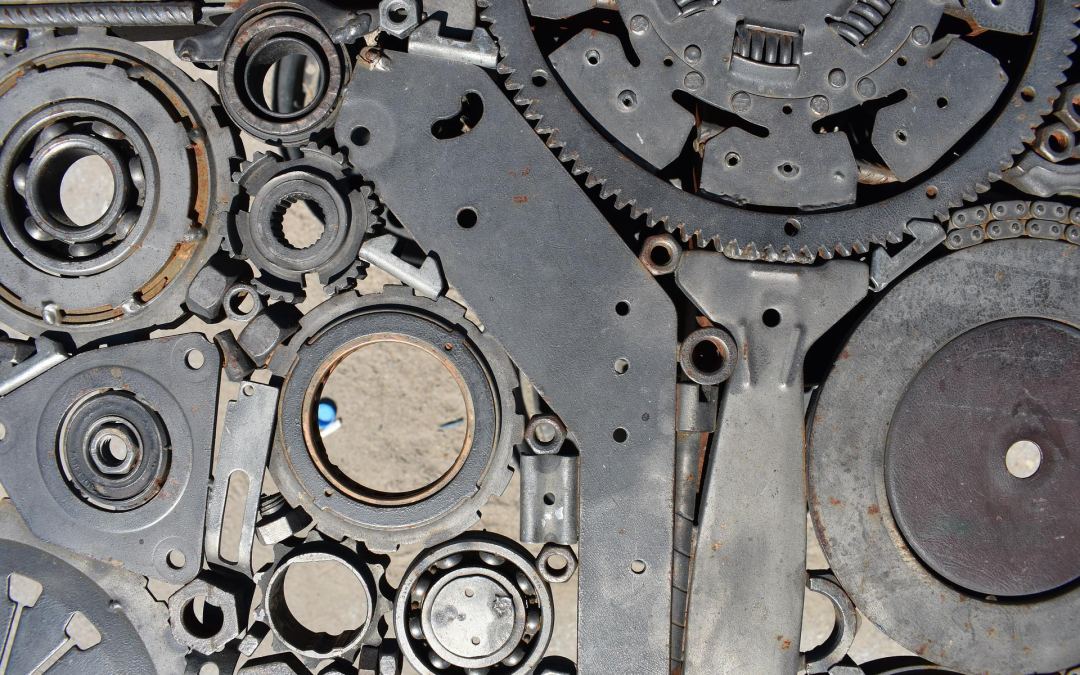

by Metal Mechanical Finishing | Oct 20, 2021 | Deburring, Metal Finishing

Deburring can be accomplished in a variety of ways, depending on the material, component geometry, burr size and location, product volume, and cost. Deburring is done in a variety of ways, including manually and mechanically. Non-conventional technologies for...

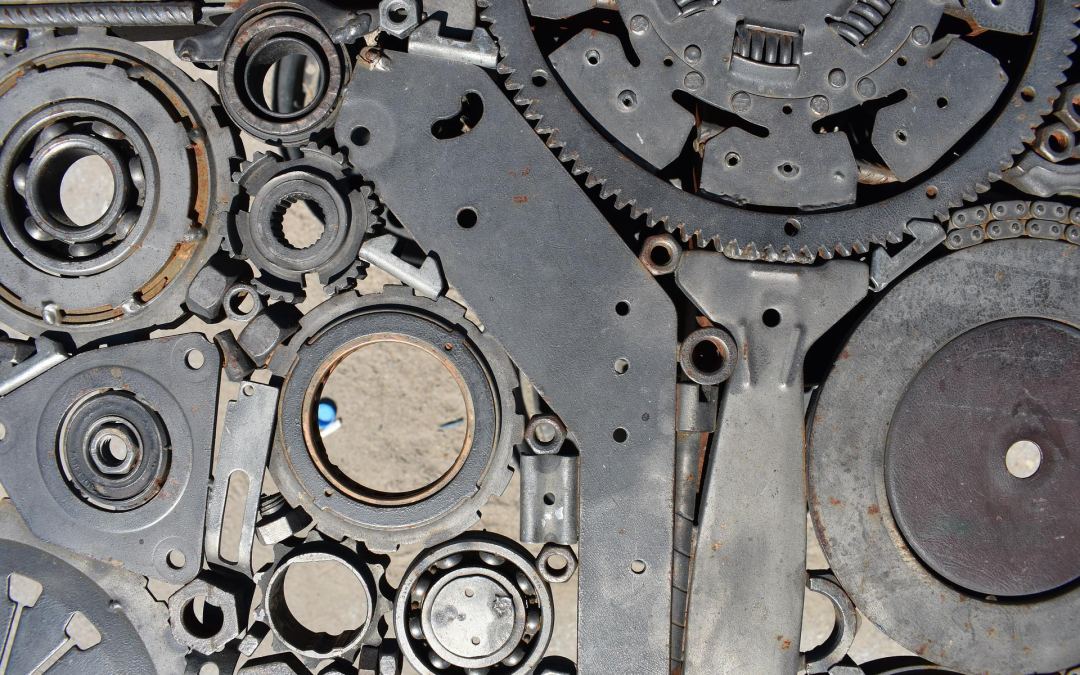

by Metal Mechanical Finishing | Sep 9, 2021 | Deburring, Metal Finishing

Deburring is an essential part of the production process for many reasons, including (but not limited to): Deburring allows for the right fit and assembly of parts Parts are prone to cracks and fatigue because of burrs acting as failure initiation sites...

by Metal Mechanical Finishing | Aug 18, 2021 | Deburring, Metal Finishing

There are many different kinds of metals that we use in some way on a regular basis. Some of these metals include copper, tin, zinc, lead, and nickel— as well as the considerably rare “precious” metals such as silver, gold, platinum, and palladium. All of these metals...